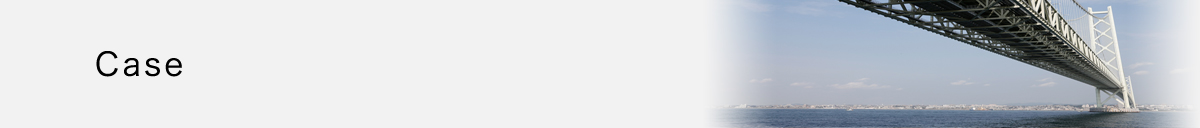

Development of one of the largest logistics facility in Japan Experts leading the Nagareyama Project

A large-scale logistics facility construction project was launched near Nagareyama IC in Chiba Prefecture. As the design supervisor, F&P technical team, consisting of design, facility, structure, and construction, was assigned as a design supervisor of the project.

What is their work at the forefront of the Nagareyama Project, a large-scale project built over a long period of time?

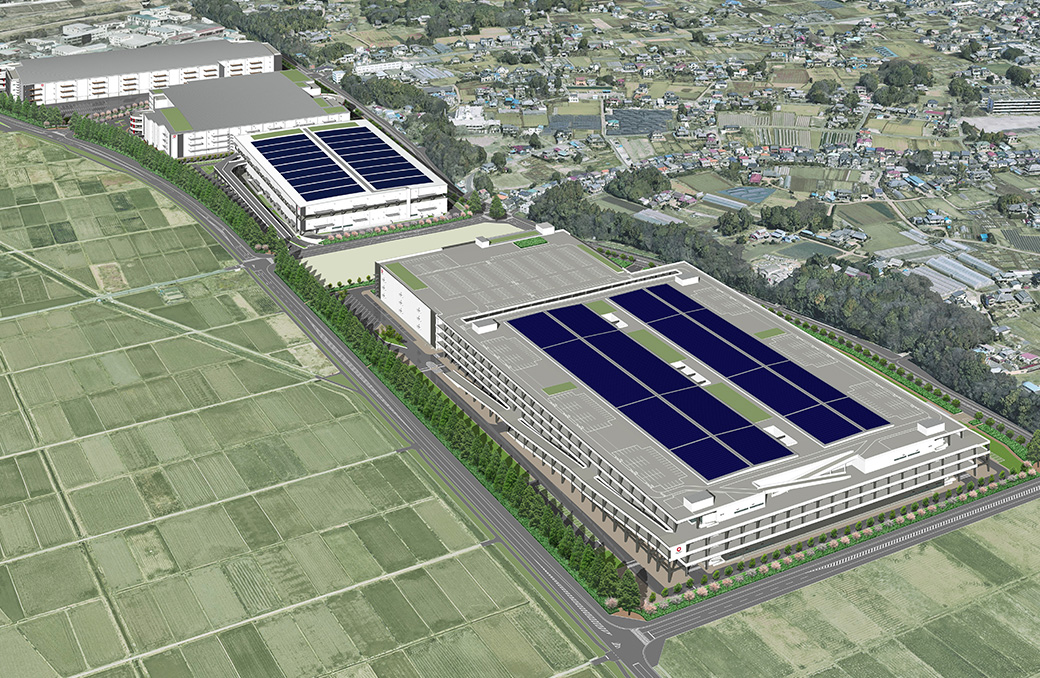

Located 2.7km from Nagareyama IC. It will be a distribution hub that can cover a wide range of areas, deliveries from central Tokyo to eastern Japan area, taking advantage of its location within a 25km radius of the metropolitan area. Based on the concept of a logistics facility that supports child-care, the facility is fully equipped with a nursery and convenience store for tenant employees.

Taking into consideration BCP, a seismic isolation systems and emergency generators was installed.

Using the disadvantages for urban development

A group of warehouses gathered near Nagareyama IC. The plan for a logistics facilities, which was divided into four separate constructions by Daiwa House Industry Co., Ltd., was launched around 2015. F&P was also part in the development of each facility, and at autumn 2020, the fourth facility is planned for construction to start.

The area surrounding the interchange used to be an area with land use policy that was not suitable for building for commercial use, such as the 10m height limit of construction, due to the spread of paddy fields. However, in accordance with the policy change of the city master plan of Nagareyama City, we repeatedly discussed and not only requested with the city but also presented a flood control plan which was incorporated into the development. We proposed that the town should be built in a whole area.

Such efforts have been fruitful, and the restrictions have been relaxed due to changes in the city planning master and landscape plan from the land that was not suitable for logistics facilities. Beginning with these changes, the integrated circuits have been developed as the distribution center district.

Working with knowledge and experience to create our largest logistics facility project

Nagareyama IV, the largest facility of theⅠ-IV series, has a floor space of more than 30 million ㎡, one of the largest in the country, and also is the largest size for F&P, which we have been involved in numerous logistics facilities.

Mr.Yukawa, who is in charge of IV’s facility structure, said, “If there are many things that are needed then, there is as many things that we need to check,” and “I think it took about six months just for the piles to be driven into the ground to increase its strength.”

That number of piles adds up to 761 piles.

In addition, since precast concrete ❋ is used, the drawings of the parts and materials to be manufactured at the plant must be checked in parallel with the on-site inspection, and it is said that the figures are consistent with the detailed figures in the drawings that reach a large amount every day.

Mr.Taira, in charge of the facility, says, “Because of the large size, we installed a system with a scale of electric power supply or low voltage electric power facilities that are usually not used in an ordinary scale facility.”

In addition, he said, “In order to acquire LEED Gold Certification, it was featured by installing lights that automatically turn off daylight with daylight sensors and by using rainwater for the toilets,” and he responded to the high demands of customers as a facility designer.

Mr.Kurihara, who is in charge of design, said, “It’s because there are so many people involved on a large scale that it’s important to move in steps. We have to discuss in millimeters, even if the building is large, and customers’ requests vary. I’m responsible for exchanging opinions with everyone.”

Rapid plan changes are frequent and must be coordinated with each area while fine-tuning on-site.

There seems to be a shadow of difficulty that cannot be expressed in words.

Nagareyama IV was completed in October 2021.

For about two years and two months before completion, each experts worked hard to build a large-scale logistics facility on a daily basis at the site where the work continued without a break.

※ Precast concrete construction: A construction method in which building materials are manufactured in advance at the factories, and are transported and assembled on site. Compared with the conventional method, it leads to uniform quality and labor saving

※LEED:Abbreviation of “Leadership in Energy & Environmental Design.” A system for evaluating energy conservation and environmental impact from the planning, construction, and operation of buildings. There are four levels of certification from platinum to standard.

There are many people who currently take charge of multiple building projects, and they are highly trusted members.